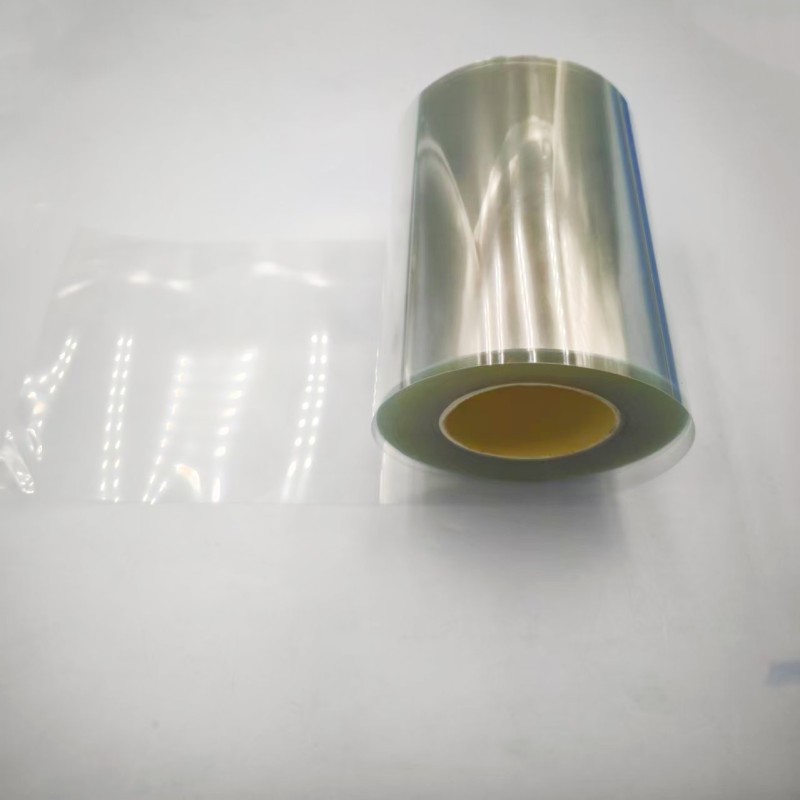

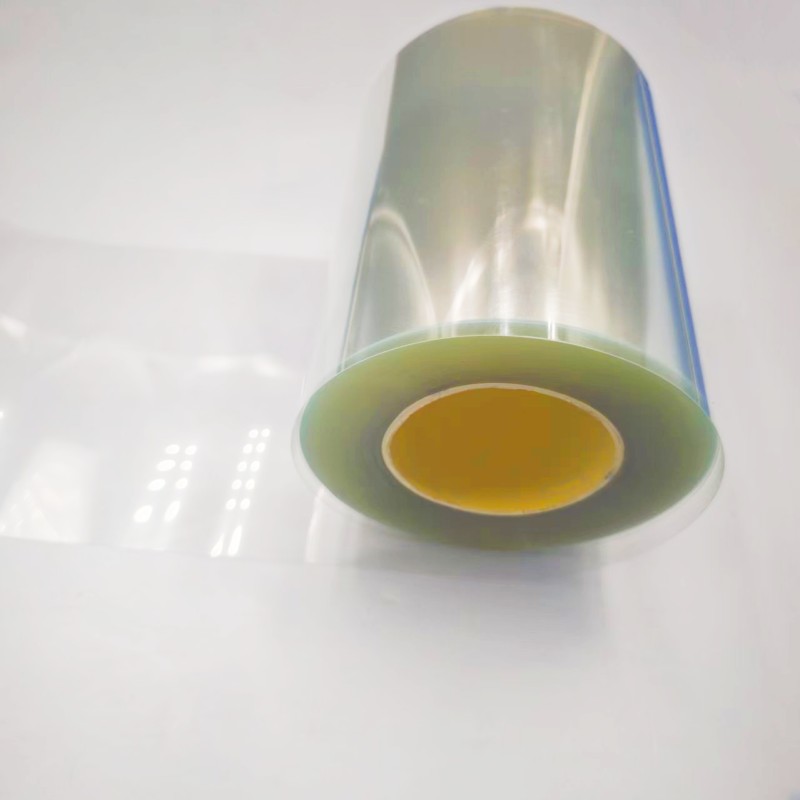

Pellicola di polistirene trasparente BOPS/OPS Foglio rigido

2025-06-24 13:29BOPS, or Biaxially Oriented Polystyrene, refers to a type of plastic film that undergoes a biaxial stretching process during manufacturing. This stretching technique imparts unique properties to the film, making it ideal for a wide range of applications. BOPS film is known for its transparency, stiffness, excellent dimensional stability, and good barrier properties.

Packaging Industry:

One of the primary applications of BOPS film is in the packaging industry. Due to its exceptional clarity and stiffness, BOPS film is commonly used for packaging food products, pharmaceuticals, cosmetics, and other consumer goods. Its transparency allows consumers to view the product inside, enhancing the visual appeal of the packaging. Moreover, BOPS film provides excellent protection against moisture, gases, and other external contaminants, ensuring the integrity and freshness of the packaged items.

Labeling and Printing:

BOPS film also finds extensive use in labeling and printing applications. Its smooth surface and dimensional stability make it an ideal substrate for high-quality printing, ensuring vibrant and crisp graphics. BOPS film is often used for labels on bottles, containers, and other products where visual appeal and durability are crucial. Additionally, its stiffness prevents wrinkling or warping during the labeling process, ensuring a professional and attractive presentation.

| Attribute | Description |

|---|---|

| Product Designation | BOPS Film: Elevating Performance for Versatile Applications |

| Material Source & Quality | Crafted from premium 100% Biaxially Oriented Polystyrene (BOPS) for exceptional clarity, flexibility, and industry-leading quality. |

| Manufacturing & Texture | Utilizing advanced biaxial orientation technology, our films boast a smooth surface with options in Clear and Matte textures, catering to diverse visual standards. |

| Size Variety & Customization | Explore a vibrant spectrum of colors, including Clear and Transparent options. Size options are extensive, featuring a popular specification of 2mm x 200mm x 50m/roll, with the flexibility of tailored sizing for specific project requirements. |

| Versatility Across Industries | Engineered for adaptability, BOPS films find applications across diverse industries, providing flexibility and usability in manufacturing, packaging, and beyond. |

| Durability & Longevity | Boasting excellent durability, our films offer a reliable and long-lasting solution, resistant to wear and tear in various environmental conditions, ensuring longevity across different applications. |

| Ease of Installation | Designed with user-friendliness in mind, our BOPS films seamlessly integrate into processes, optimizing efficiency during installation and use. |

| Environmental Considerations | Committed to eco-friendliness, our BOPS films are crafted from recyclable material, contributing to sustainable practices in the industry. |

| Hygienic Properties | Easy to clean and maintain, our films promote a hygienic working environment, making them ideal for applications where cleanliness is paramount, such as in food packaging. |

| Chemical Resistance | Exhibiting superior resistance to chemicals, our BOPS films ensure the integrity of the material in the presence of various substances, making them suitable for diverse industrial environments requiring chemical resistance. |

| Customization Options | Tailored options are readily available to meet specific design requirements, providing unparalleled flexibility for unique projects and applications. |

| Safety Features | Engineered with safety in mind, our BOPS films offer attributes like fire resistance and compliance with relevant safety standards, ensuring a secure environment for various applications. |

| UV Protection |