TL-PP-303 Applicazioni del polipropilene (PP) nell'incisione laser

Resistenza alle alte temperature

Tuttavia, il polipropilene è resistente al calore, il che lo rende un buon candidato per l’incisione laser; cioè, può toccare le temperature create durante l'incisione senza deformare o influenzare le proprietà di base del materiale. In quanto tale, non si verifica alcuna deformazione delle forme o perdita delle proprietà del materiale, e si ha la certezza che i disegni incisi appaiono nitidi e puliti per non avere molta distruzione del materiale.

- TOPLEADER

- CINA

- 15 GIORNI LAVORATIVI

- 5000T/M

- informazione

- video

- Scarica

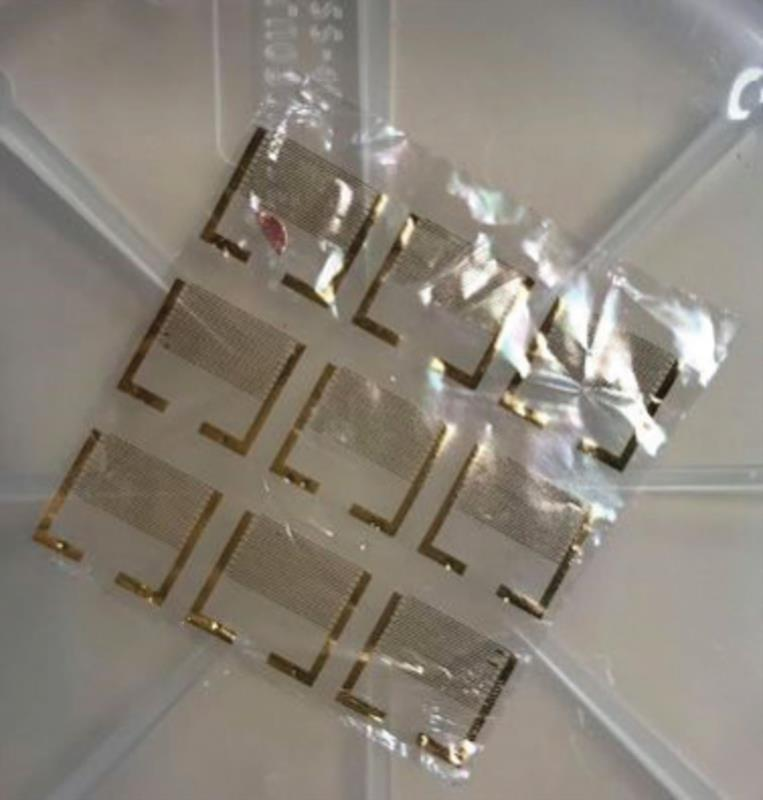

Applicazioni del polipropilene (PP) nell'incisione laser

Il polipropilene (PP) è una plastica molto popolare grazie alla sua vasta gamma di buone proprietà che la rendono adatta all'uso in moltissime applicazioni, inclusa l'incisione laser. Alcune delle proprietà del PP, quindi, che realizzano la sua maggiore applicazione in questo settore includono ma non sono limitate a;

Efficacia in termini di costi

Il polipropilene è un materiale conveniente, il che lo rende un'opzione economica per qualsiasi progetto di incisione laser. Il suo rapporto costo-efficacia consente ad aziende e hobbisti di creare prodotti di qualità incisi al laser senza incorrere in costi elevati.

Non tossicità

La sicurezza è un aspetto critico nella selezione dei materiali e il PP è un materiale non tossico. Non emette fumi pericolosi nell'ambiente di lavoro, offrendo quindi ridotti problemi di sicurezza per gli operatori e per i prodotti finali. Ciò lo rende particolarmente adatto per applicazioni negli imballaggi alimentari, nei giocattoli per bambini e nei dispositivi medici.

Resistenza all'usura

Il PP è noto per essere uno dei migliori materiali per resistenza all'usura. I prodotti incisi sviluppati in PP possono resistere all'uso quotidiano senza danneggiarne l'aspetto, dai piccoli articoli come articoli promozionali agli articoli industriali.

La resistenza alla corrosione del PP è buona e viene utilizzata in ambienti in cui è coinvolta un'esposizione più o meno costante a sostanze chimiche e umidità. È un modo per garantire che i materiali PP incisi siano ben curati anche in termini di estetica e utilizzo nelle diverse condizioni, ad esempio, in condizioni difficili nei laboratori o altro.

Resistenza agli urti

La forte resistenza agli urti del polipropilene assicura che i prodotti incisi non si danneggino facilmente a causa di cadute o urti. Questi fattori rendono il PP un materiale ideale per articoli che devono resistere a maneggiamenti difficili, come etichette per bagagli, componenti industriali e molti beni di consumo.

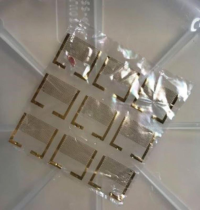

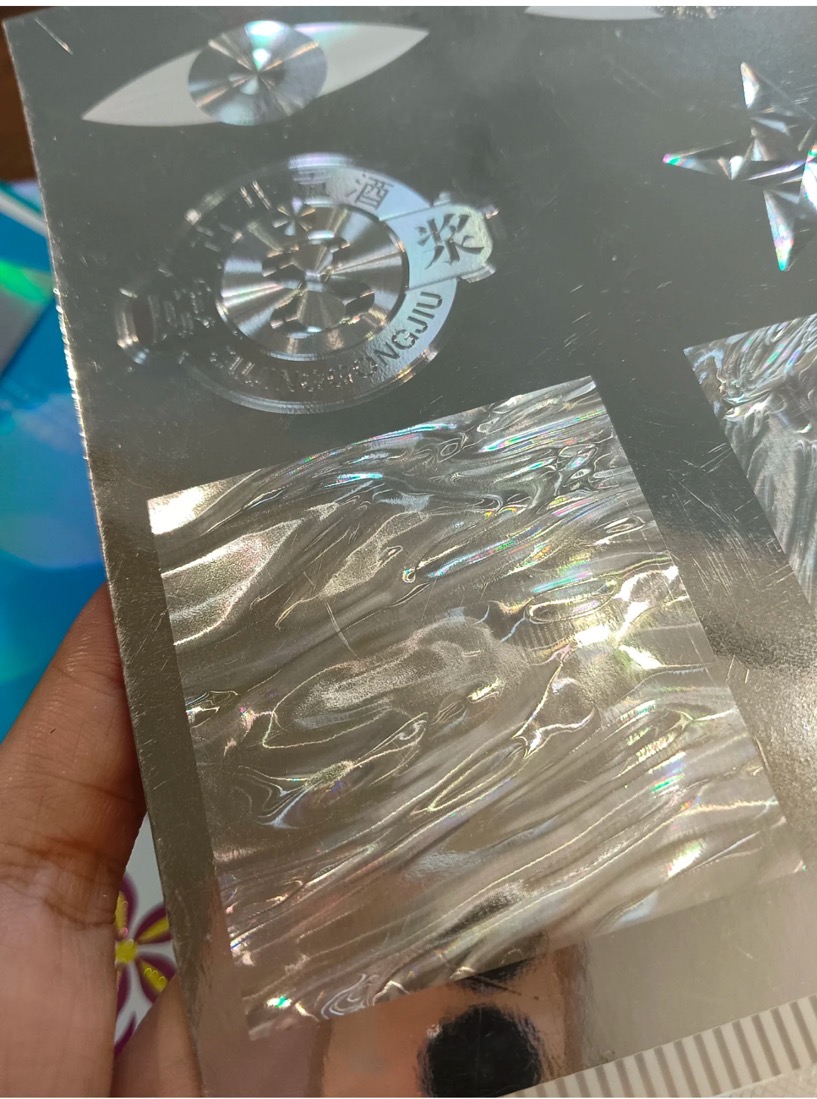

Capacità di stampa

Il PP può essere stampato con un'ottima stampabilità, quindi sono possibili incisioni dettagliate comparativamente con la massima qualità possibile. È consentita l'incisione di un modello individuale, di un logo specifico o di un testo che possa essere molto dettagliato e di alto valore.

Resistenza alle alte temperature

Tuttavia, il polipropilene è resistente al calore, il che lo rende un buon candidato per l’incisione laser; cioè, può toccare le temperature create durante l'incisione senza deformare o influenzare le proprietà di base del materiale. In quanto tale, non si verifica alcuna deformazione delle forme o perdita delle proprietà del materiale, e si ha la certezza che i disegni incisi appaiono nitidi e puliti per non avere molta distruzione del materiale.

Conclusione

Questo riepilogo mostra che è molto conveniente, non tossico, resiste all'abrasione e alla corrosione, resiste agli urti, è stampabile, rientra nell'intervallo accettabile di alta temperatura e, pertanto, rende il materiale in polipropilene ottimo per eseguire l'incisione laser. Tutti questi parametri garantiranno il fatto che non solo i prodotti in PP sono convenienti e sicuri, ma forniranno anche un servizio per un lungo periodo e manterranno un valore estetico. Ecco perché il polipropilene nel settore dell'incisione laser sta diventando sempre più popolare ogni giorno, offrendo flessibilità e affidabilità nelle applicazioni.

Entro 15-20 giorni dopo il pagamento ricevuto...more